The Best Guide To Premier Aluminum Llc

The Best Guide To Premier Aluminum Llc

Blog Article

Some Ideas on Premier Aluminum Llc You Need To Know

Table of ContentsRumored Buzz on Premier Aluminum LlcPremier Aluminum Llc for DummiesThe Greatest Guide To Premier Aluminum LlcThe smart Trick of Premier Aluminum Llc That Nobody is DiscussingAn Unbiased View of Premier Aluminum Llc

When choosing an aluminum shop for your production requirements, it's essential to research a number of variables. One of the most important aspects to think about is the experience and skills of the foundry. Selecting a shop who has the appropriate expertise of the light weight aluminum casting procedure, and the profile to show for it, helps to have an effective end result for your job.Having the experience and sector understanding to engineer your spreadings for optimal production and quality outcomes will improve the job. Producing aluminum spreading requires a complex set of procedures to accomplish the best results. When determining on a new light weight aluminum shop to companion with, guarantee they have extensive market experience and are educated regarding all facets of the aluminum casting process: layout, production, material evaluation, and item testing.

The factory should likewise have a tested performance history of delivering remarkable products that satisfy or go beyond client expectations. Quality control ought to additionally go to the top of your checklist when selecting an aluminum foundry. By functioning with a qualified factory that complies with the standards for quality assurance, you can secure the stability of your item and guarantee it satisfies your specs.

An Unbiased View of Premier Aluminum Llc

This certain process can be automated and duplicated. Numerous elements that extremely complicated forms can be manufactured utilizing this procedure. Large quantities of components can be produced in just a brief period of time. Before you start browsing for a trusted light weight aluminum pass away wheel, there are some crucial points that you need to do.

You have to ask yourself what kind of light weight aluminum die spreadings you require. After establishing what you call for, you need to specify the specs of the light weight aluminum die castings you need. Establish the weight, density, dimension, and other specs of the light weight aluminum die-cast you need. It would likewise be far better if you might attract and show all the dimensions of the light weight aluminum die-cast.

Do you understand exactly how much money you have to invest on the items? In order to do this, the most effective thing to do is to identify how several light weight click this link aluminum diecasts you need. After having this details, you can start investigating light weight aluminum die-casting suppliers. You can do this by merely inputting the key phrase" Light weight aluminum die casting producers" on the Google search engine.

Several of the inquiries you require to ask yourself are whether they have actually experienced and trained drivers, the length of time their business has actually functioned, or if they have some achievements. You can typically get the solution to these inquiries from the supplier's internet site. You can research various other internet sites or external resources to confirm if the details supplied on the manufacturer's internet site is authentic.

3 Easy Facts About Premier Aluminum Llc Explained

Another point you need to think about is the supplier's ability to create light weight aluminum die-casting items. In various other words, the quantity of products the maker can create at a given time. Several of the important concerns you require to ask on your own are whether the maker can create a greater quantity or can the maker meet your demands.

(https://pubhtml5.com/homepage/lekm/)Suppose your firm needs 10,000 pieces of particular maker parts from the producer within one month? You got this amount; nevertheless, the supplier can just generate 5000 items of these device components within one month (Foundries in Wisconsin). Consequently, you won't have the ability to receive the quantity that you purchase promptly

What Does Premier Aluminum Llc Mean?

It is crucial that you must ask if the producer is carrying out an in-house tooling procedure. Additionally, you need to ask the supplier exactly how much the cost of in-house tooling is. The in-house tooling procedure, which allows you to develop distinct layouts and forms can be an added expense.

This element straight associates with the producer's production capacity. Aluminum Castings. You have to look for a maker that can make sure quicker delivery of items.

This suggests that there are a number of alternatives that you can pick from. That is why it is significantly advised that you must choose a maker that can generate different types of light weight aluminum die-cast products.

Our Premier Aluminum Llc Diaries

A lot of commonly, these light weight aluminum die-casting products will call for some designs, machining, or finishing touches. Having this in mind, you should try to find a manufacturer that can execute a variety of additional ending up works when pass away casting is done. Some examples of ending up procedures consist of Chromating, CNC Machining, Sandblasting, Powder layer, Anodized, E-coating, Wet paint, Plating, and numerous more.

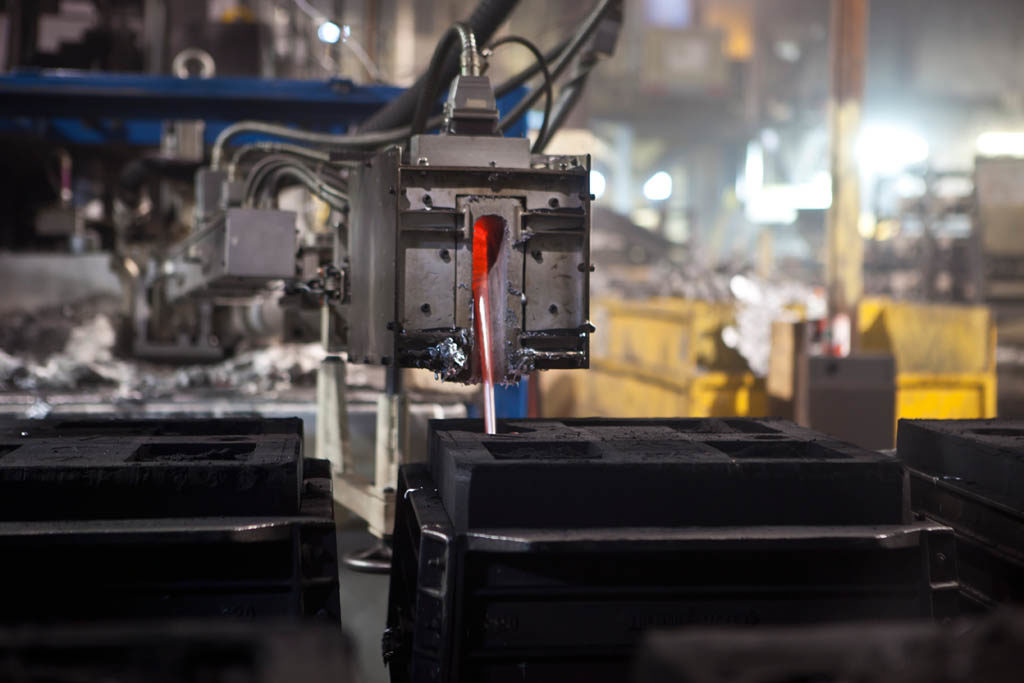

Pass away casting is one of one of the most cost-efficient, exact, and protean production processes on the planet minute. The process involves fitting molten essence, under stress, into a relevant die (earth), and formerly solidified it can be ejected and ended up (if necessary) in a variety of ways. The passes away are [...]. Report this page